Business owners and other interested parties were recently given the chance to test and learn more about the state's only “high-pressure processing” machine.

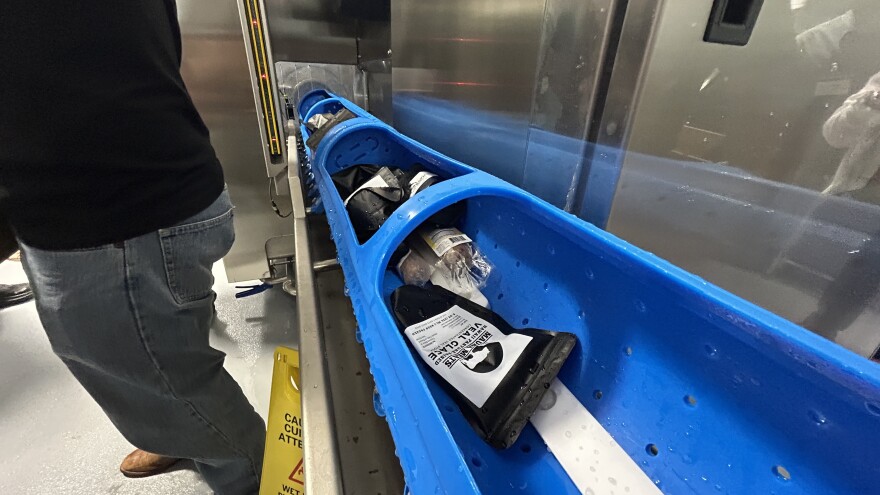

They gathered last week in Wahiawā during a food summit at Leeward Community College's Value-Added Product Development Center, where the machine is housed.

"We are especially interested over here at the HPP summit and how we can extend the shelf life of a lot of our products because what we try and do is make clean-label items, things that don't have a lot of preservatives inside, or we're trying to not use phosphate diacetate," said Micah Richards, owner of Mauka Meats, at the summit.

"When you look at the ingredient label and see something that has 12 syllables on it that you have to look up on Wikipedia. We're trying to make food, food again."

Richards sells meat-derived products — like sausages, cured meats, and broths. They can last for about a week in a refrigerator, but up to six months if they go through “cold pressure” preservation first.

Avoiding heat and preservatives to increase the shelf life of food is a big plus for the right business.

LCC's machine can process up to 800 pounds of food per hour, and smaller businesses like Mauka Meats are lining up to use it.

But officials at the center said the relatively small machine is better suited for research and development, though commercial-sized processors could make their way to the islands in the future.

One potential for the “cold pressure” method is an improved ability to preserve and export culturally important and unique foods like poi, which can be ruined by heat and preservatives.

"Our amazing produce and fruits will have quality degradation by heat, and so we are able to preserve the freshness, all the flavor, while expanding the possibility of distribution and market access without compromising any of the quality," said Hailey Zhou, a food scientist at the Wahiawā center.